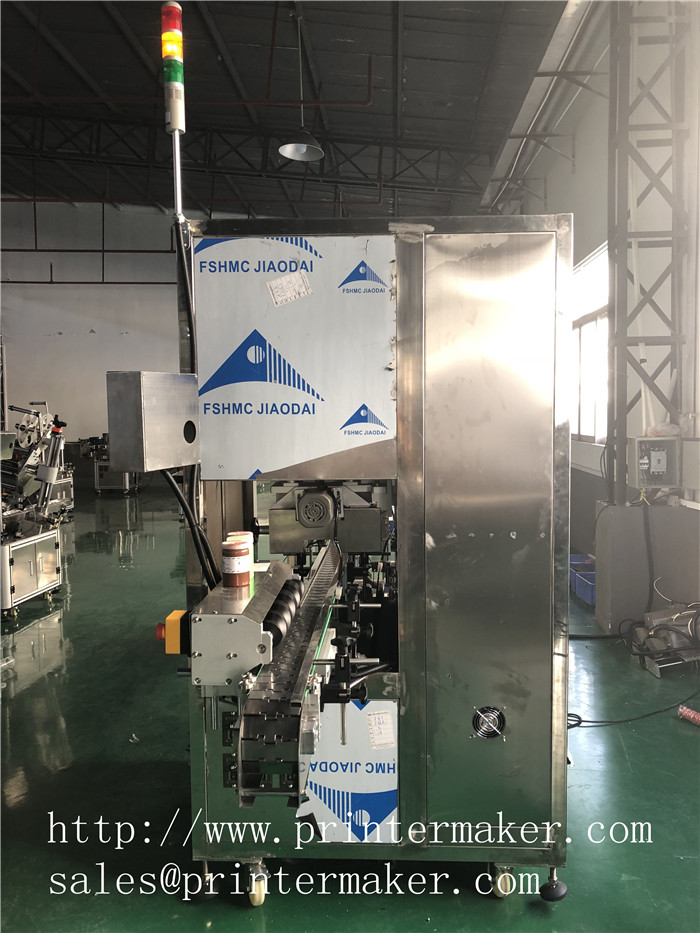

Product name:Automatic High Speed Sleeve Labeling Machine

Model Number: ALM-250

Linear High Speed Trapping Label MachineModel: ALM-250

Voltage AC220V

Sleeve labeling machine power:3KW

Production capacity:

the higher the label:label height ≤100 mm

the lower the production capacity:≥200 bottles/min

Sets of standard pass rate:≥98%

The entire line of production efficiency:≥95% (in 24-hour calculation)

Diameter of bottle:Φ28mm-φ125mm, special sizes can be extra design

Bottle height:30 mm -280 mm,special height can be extra design..

For label:PVC,PET,OPS

Label length:30mm-250mm

Label thickness:0.035mm-0.13mm

Label matherials:PVC,PET,OPS

label transparent spacing:≥5 mm

Label paper core diameter:≥5''(127mm)

OD label: ≤500mm

Sleeve labeling machine Host Dimension: L1550mm*W1055mm*H2000mm

Describe:

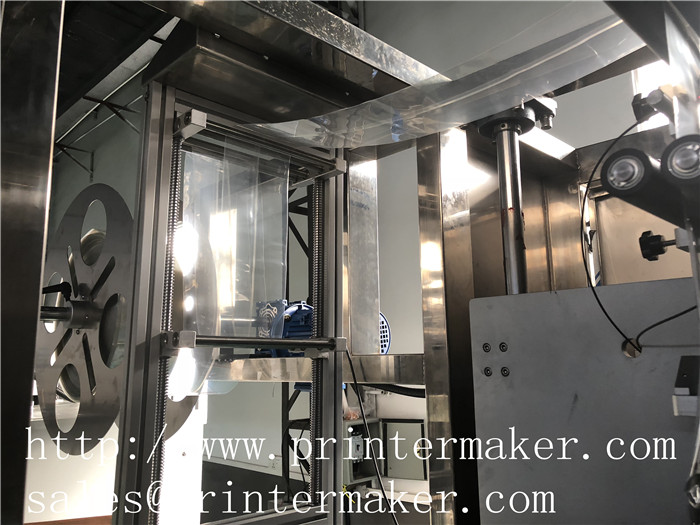

1) Full Face Stainless Steel hosts: the whole machine is not waterproof rust;

2) Adjustable cutter head: original cyclotron cut, double-sided blade, long life;

3) Single positioning center guide pillar: Tag channeled more stable;

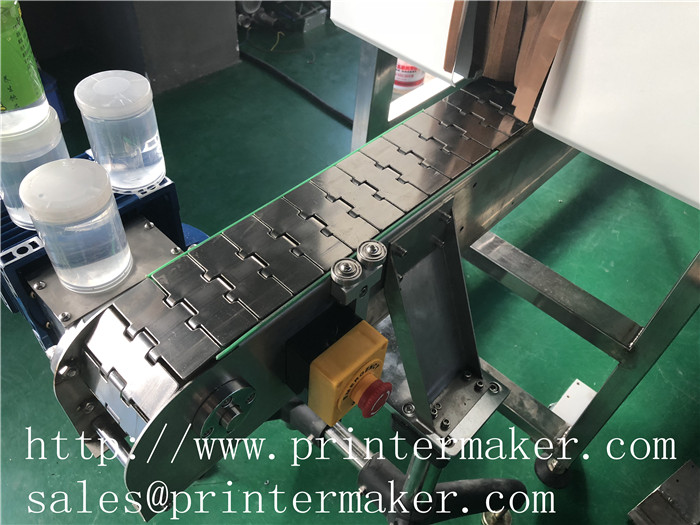

4) synchronized dividing device: bottle feeding is more stable;

5) Label brush under Group: sets of standard precision is more accurate;

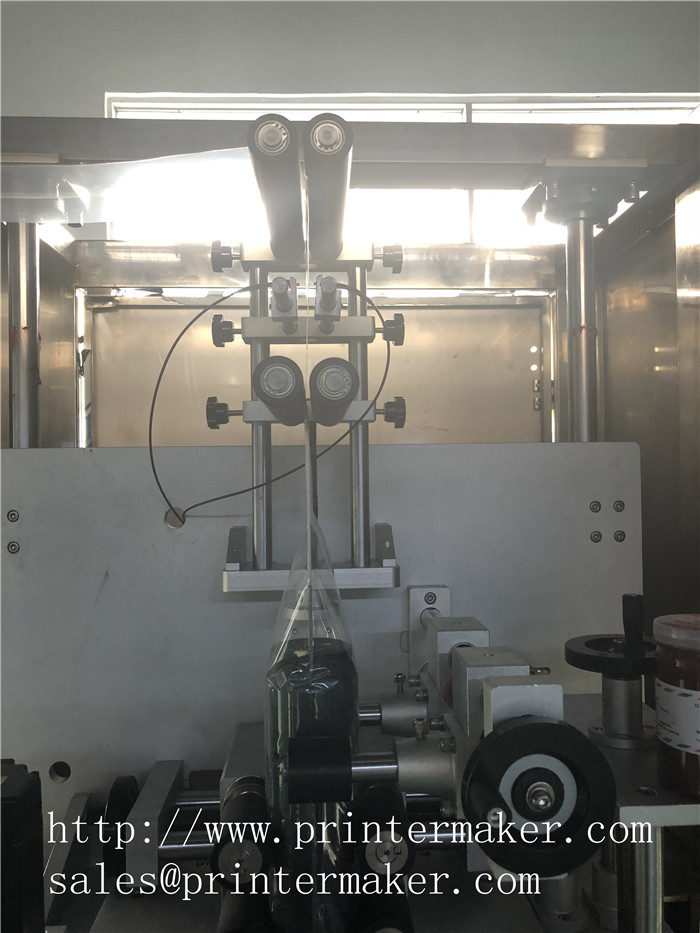

6 ) label control electric eye shelf: unique combination of tail and electric eye, improve membrane material cutting

accuracy; push-button control box: Operating more humane;

7) formula feeding rack: the freedom to choose rack position.

8) Electrical Appliance Configuration Specification

9)Adopted PLC programmable controller, imported servo motor, servo drives, inverters and sensors, in addition

to using a set of standard positioning module for accurate, fast and stable.

10) applicable set of standard varieties of type:

A variety of bottles, such as: round bottle, square bottle, flat bottle, curved bottle, cup and so on.

Working principle

When push bottle electric eye found the bottle over and that there is a continuous production when necessary, into the bottle screw into operation push the bottle (screw into the bottle's role is equidistant from the bottle will not be equidistant from the new initial velocity of bottles, etc.), bottle into the sleeve labeling system is the core unit, when the sets of standard electric eye sensor to have the bottle over, immediately transfer the information to the control center PLC, and the PLC were continuously issued four directives: sent standard, positioning, cutting mark, shot mark, when shooting marked the end of a process of complete sets of standard bottles, then enter the label finishing, shrink unit.

Features

(1) Highspeed stability, long life: it is a unique smart technology, compact design in the industry described as thriving, this unique sleeve labeling machine designed to provide a high-speed operation is technically strong support. Spare parts are used world-renowned brands, especially electrical control system part of the user is responsible for their credibility responsible, using all relevant industrial sectors top product, a fundamental guarantee for the quality of the performance of the equipment, in addition to its unique closed design , not only in the course of the operator, while the equipment system itself also played a good protective effect, greatly extending the life of the equipment.

(2) Good safety performance: The new sets of standard machine in the design process fully reflects the machine harmonious design, production process, equipment operation, always in a unique design protection systems under improper operation if artificially bring security hidden, its safety system automatically detects and immediately stop operation, must be restored by detecting recognition may continue.

(3) Using a wide range: in the effective range of the folding path, whether packaging is circular, square or other shaped form, made of glass, plastic, can be applied.

(4) Running cost: a machine bottles, the entire device is unique only cutter wear parts, easy access, easy to replace, the cost burden is low.

(5) Replace the packaging easy: modular design for mold, a mold bottle mold free use of any tool more, just some simple hand movements to adjust to.