- PRODUCT DETAIL

- Video

- Packing Photo

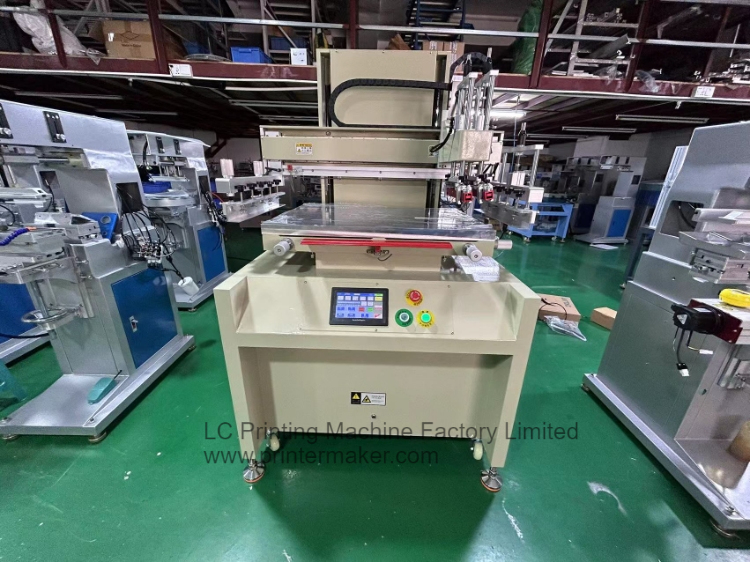

Product name:Flatbed Screen Printing Machine with Panasonic PLC and ABB Servo Motor

Model Number: SP-5070PLC

Description:

Flat Vacuum Worktable Screen Printer(500mm x 700mm)

This is the new generation of flatbed vacuum screen printing machine which is newly upgraded with Panasonic PLC control, ABB servo motor and SMC brand cylinder. It is suitable for those products which is enjoying the precise screen printing on substrates such as PCB Board, IC board, Sheet, Film or Cube forms which with smooth flat surface and made of as metal, plastic, ceramic, glass, wood etc... It is widely used in electronic industry, advertising, packing & printing, toy, stationery, gifts, industrial arts fields etc...

Screen printing objects such as resistor, keyboards, advertisement sheet,T-Shrit, large size of cardboard sheet, flat convers, doors, tables, silica gel keypads, paster, sticker, nameplate, panels, Plastic Moldings etc.

Feature

1. Vertical structure, Compact & space-saving. The famous brand Panasonic PLC control, easy operation and good stability. Language optional, English or Chinese Operation Panel.

2. Printing driven by Japan original Fuji servo motor, Installed Linear Guide or Linear Guideway. Printing speed and ink flooding speed are adjustable. Running smoothly and a long work life.

3. Japan SMC brand cylinder for the squeegee in most stable and long run lasting running.

4. The motor drive screen frame up and down, two poles guide. Separated buffering air course to keep stability register.

5. Duralumin working table( made according to the international standard cast aluminum JISH5302-2000 ), precise scale micro-adjustable. Planeness keep in 0.05mm, roughness

6. Printing angle/ printing pressure and spacing between screen frame and table are adjustable.

7. Reliable safety device is installed according to CE standard.

Specifications

1. Thickness of printing matter: 0~120mm

2. Size of working table:500×700mm

3. Max Printing area:450×650mm; Minimum print size: 100*160mm

4. Max Stroke of up-and-down frame:160mm(Customizing)

5. Max. printing speed:1500pcs/hour

6. Air pressure:6 Bar; Air consumption: 0.4kg

7. Power voltage: AC 380V, 3phrases (220V,60HZ, 3 Phrases power supply is available)

8. Power Rate:2.5KW; ABB vacuum motor: 750W

9. Machine dimension:1100×1050×1600mm

10. Packing size:1200*1100*1800mm

11: Left&Right Rail stroke: 800mm

Price Terms : FOB Shenzhen or Guangzhou

Payment Terms : Western Union ,T/T or L/C

Packing : Wooden case

Lead Time : Within 3 days

Standards Certificate : ISO9001-2000,CE

Machine Fittings:

1.One aluminium screen flame

2.One Manual in English

3.One set of tool

Package List

Wooden case :1450 ×1120 ×1850 mm

Gross Weight: 480Kg

Ship Date

1.By sea

within 30 days after receive remittance

2.By air

within 6 days after receive remittance

Warranty

1.Cylinder can be changed for free within 1year,freight collect.

2.Other parts can be changed for free within 2years,freight collect.

3.Warranty period:3years