Different of Closed Ink Cup System Pad Printer and Open Ink Cup System Pad Printing Machine

Different of closed ink cup system pad printer and open ink cup system pad printer

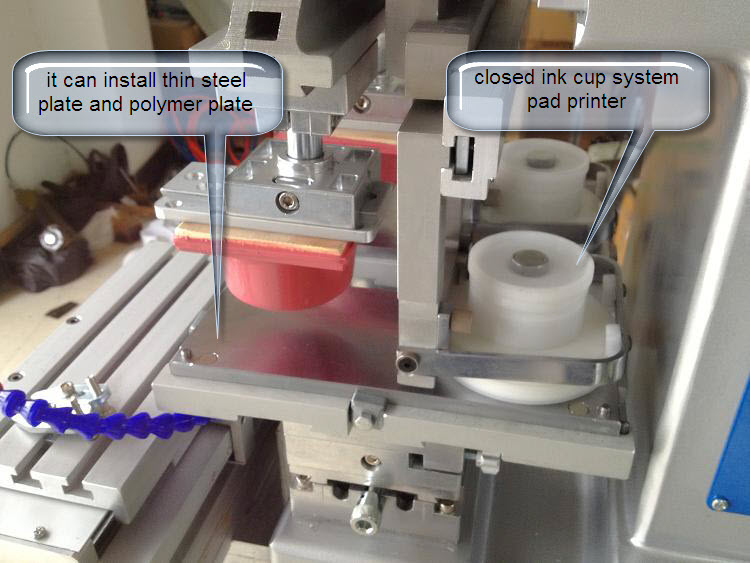

Closed ink cup system pad printer construction as below picture:

It have many advantages than open ink cup system:

1. It can save ink

2. It is good for environment and health.You will not smell ink pungent odor when the pad printer is working.

3. It will so easy to make a logo on the plate,you can choose steel plate or polymer palte to make logo on it.The polymer plate is environmental material. just expose plate by exposure machine, and clean plate by water.If you choose thin steel plate,so you will prepare thinner,photosensitive liquid, developing liquid,etching liquid to make logo on it.

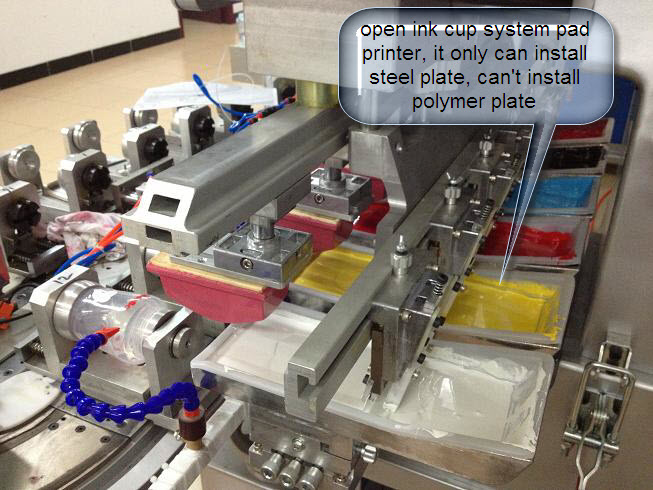

Open ink cup system pad printer construction as below picture:

Open ink cup system is cheap and economic printing way on the pad printer.It only can install steel plate , can’t install polymer plate.The ink tray is open, so the ink smell is sporadic.

When you want to make logo on the steel plate , so you will prepare thinner,photosensitive liquid, developing liquid,etching liquid.exposure machine.